Air compressor is a handy thing and it could help you in different ways. It is so essential that almost every home now own an air compressor. This is a machine that works for compressing air. In most cases, it compresses the gas for increasing pressure. As machines have different parts, any machine in the world will make some noise.

Air compressor that comes with a high price used to make less noise. But those are not affordable for everyone. So, I was looking for something useful that can hack the mechanism to reduce noise. This article will tell you why your air compressor makes noise and how can you reduce the noise like a pro.

Table of content: Air Compressor Noise Reduction

- What is the Level of Air Compressor Noise?

- What Causes Noise in an Air Compressor?

- How to Reduce Air Compressor Noise-7 Hacking Tips

What is the Level of Air Compressor Noise?

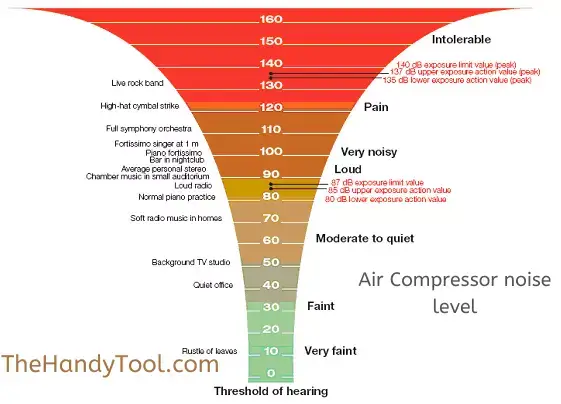

Before we go to further details, it is essential to know when to consider that the noise is too much to tolerate. Well, whenever it is something about sound, the international standard for measuring is decibel (dB).

If your air compressor is making noise below 70 dB, this can be considered as tolerable. This is not too much for the home environment. However, you may want to have more calmness at home.

But there are also some cheap and old products on the market. Those products are not optimized to perform quietly. As a result, you may notice there is a huge noise level in the compressor which is intolerable.

Usually, when you are using a typical air compressor at home, it can make noise level up to 95 dB which is too high to tolerate.

How would you find the noise level of your air compressor? Well, this is an easy job. You can even measure it with your smartphone. There are some popular apps in app stores that can measure the noise level. Go for one and identify what is the sound level of your air compressor. You may also use some professional tools.

What Causes Noise in an Air Compressor?

So, now you have a clear idea when to worry about the noise level of your air compressor. This is the time to know what causes the situation. Well, several factors affect the noise level of an air compressor.

If those factors are the issues in your case, you may solve them efficiently. Here is the list of the factors that affect the sound –

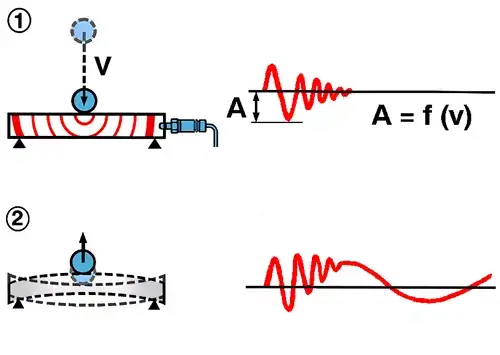

Vibration

– The first basic cause of higher noise in an air compressor is the vibration of the whole machine. Though it won’t be the main factor, still this is a considerable issue of making noise. The vibration of an air compressor mainly depends on the fitting and the type. If you have assembled the air compressor in the wrong way, there is a good chance that it will start vibrating a lot.

Again, you may have assembled and installed the air compressor in the right manner, still, it can make much noise because of some parts of the machine. If any part of the machine is not attached properly with the compressor, the vibration level increases. This is also related to the placement. The hard surface doesn’t absorb the vibration and it increases. As a result, the total noise level increases.

Materials of the Air Compressor

– The raw materials used in the construction of air compressor plays an important role. For instance, if you buy a cheap product that is made from thin metal materials and you are using it at home, be sure that the item will make much noise. The reason behind this thing is, when the metal is thin it vibrates more and makes more sound.

On the other hand, some popular brands produce air compressors with the top quality materials. They used to use only thick and high-quality metal. The benefit is, that it will vibrate less. As a result, the noise level remains in the tolerable range.

Where It is Placed

– Noise of an air compressor hugely depends on the place where it is kept. For example, if you have kept the machine on a hard surface, probably it will make more noise during the run time.

Also, things that shake a lot during operation can increase the noise. Moreover, if the surface is not even, the air compressor won’t set properly. Make sure that you are setting the compressor on an even surface.

Intake

– The intake component of an air compressor is also considered as a noise increasing fact. If you compare it to a vacuum cleaner, the working process is similar. Air compressors also such air during their operation. This can cause a huge noise.

Exhaust

– Exhaust is considered one of the loudest components of an air compressor. An air compressor that doesn’t have the proper exhaust system will make intolerable noise.

How to Make an Air Compressor Quiet-7 Hacking Tips

As a user of an air compressor, you can take several steps to solve the noise problem. Here I am going to share the top 7 ways to reduce noise and keep it at the tolerable level.

Use Rubber Grommets On the Air Compressor

Rubber is a popular noise absorbing material that widely uses in different machines. For instance, you will find stainless steel kitchen sinks come with rubber coating under it for reducing noise. The same can be possible for an air compressor.

The thing you have to do is place the rubber grommet between the air compressor and the surface where it is placed. Next time when you are operating the air compressor, the rubber will minimize noise by reducing vibration.

Placing the rubber requires accurate measurement. Make sure that after placing the rubber, the entire thing is remaining flat. If everything is done properly, you can expect to reduce the noise. It won’t go silent but the noise level will be tolerable.

If you are thinking about where to buy this rubber thing, nothing to be worried. It is available at any tool store. You can also find them in online stores.

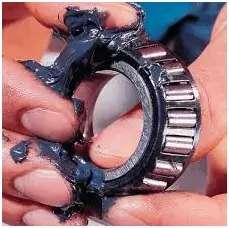

Lubricant the Bearings

It is not surprising that any machine that has move-able parts also have some bearings. The same goes for an diy air compressor. So, when you are running the compressor, the bearings will move in different directions. At that time, there will be some friction between the metal. This will cost heavy noise if the friction is not well maintained. Otherwise, this will cause the metal decay and you won’t be able to use the compressor for a long time.

So, the thing a user can do is lubricating the bearings for minimizing the friction as well as the noise level. It is not a difficult thing to lubricate metal objects. There is a wide range of products out there that work for ensuring smooth friction between the metal. You can pick the top quality grease for bearings. Apply the grease properly and keep it for a while in rest and start the compressor. This is a simple but effective solution for noise reduction.

Place the Air Intake Outside

As I mentioned before when the compressor works, it needs to intake air as the vacuum cleaner does. This is the most common issue of higher noise from an air compressor. If you want to have a calm environment at your workplace, there is no alternative to placing the air intake outside.

We usually see most of the people are placing the air compressor in the garage, home, basement, and more places. If think about the air intake in those places, automatically the noise increases. So, you need to place the intake on a place where noise is not an issue. For example, you may use the lawn or another well-ventilated area.

For placing the intake outside, you need to pass the hose. For this, use a strong bracket to keep the hose in place. Once it is done, you should run the compressor to check if it is causing noise again. Surprisingly you will notice that the noise is now at the tolerance level.

If you find still the air intake is disturbing you, there is an effective solution for it. you need to install a silencer for the air intake. Though it will cost you some extra bucks, you will enjoy the calmness of your workplace.

Keep the Air Compressor in a Distance from Your Workplace: For any kind of noise at any machine, if you go near to the machine, noise can be hard so loud. But when there is a minimum distance between your position and the air compressor, you will hear less sound.

So, the thing you should do is installing the air compressor to a distant place from your main workplace. However, in this case, you may need to use a larger hose that can flow the air to your workplace.

Sound Padding On the Wall

Previously, I have suggested placing a rubber between the compressor and the hard surface. The same you can do for the walls surrounding the compressor. Why this is effective? Well, when you place the compressor near the wall, the sound will be echoed and you will hear more noise. It will also happen when you are placing the compressor in a small corner.

So, placing something soundproof on the wall will minimize sound. In this case, you don’t have to use rubber grommets. Instead, you can use the soundproof padding on the wall. You will find some sound blanket in the stores that can work perfectly.

You don’t have to put the padding all over the wall of the room where the compressor is placed. Rather, you only have to attach the padding to the nearest wall of the compressor so that no sound echoes.

Buy a Soundproof Box for the Air Compressor

This could be an effective solution when you want to make the air compressor quiet. Even this is one of the best solutions for the noise of the compressor.

There are different types of soundproof boxes available in the market. When you are looking for the best one, make sure that you have measured the dimension of the compressor and matching it with the box.

If you don’t want to spend extra money on the box, there is a budget-friendly option for you. You need to create your own soundproof box. For this, you can use cardboard or plywood. Make the box according to the size of the compressor. Once it is complete, use rubber padding or any other sound-absorbing material surrounding the box.

Now place the machine inside of this box. This will keep the noise inside of the box and you will hear only a minimal sound which is tolerable.

Cover the Air Compressor with Soundproof Blanket

If you are unable to attach the sound-absorbing material on the wall or making a soundproof box, you can cover the compressor. For this, you need to use a soundproof blanket. Cover the whole compressor with the blanket. This will keep the noise inside like a soundproof box.

Buy a Quieter Air Compressor

If your air compressor is old and you can’t fix the noise issue with the above methods, the thing you can do is buy a new one. When buying the new product, check for the maximum noise level of the compressor. You should also read some customer feedback to know the performance.

Make sure that the maximum noise from the air compressor is within 70 dB. This level is not intolerable. You can continue your works within this limit.

Final Words

When you are trying to fix the noise issue of your compressor, remember that you are not the only one who is suffering from this issue. Almost all users of air compressor sometimes face this issue. So, follow the methods that I have shared. These methods are proven and professional workers are using them for a long time.

You don’t have to follow each of the methods of making the air compressor quieter. Follow maximum one or two methods and it will be done. However, for your ears’ safety, always use an earplug when the compressor is running. This will prevent any health issues related to noise.