An air compressor is a Handy Tool for a wide range of projects. Whenever you need air for something, you can simply turn on the compressor and complete your work. An air compressor is built with different parts and the most important part of an air compressor is its pressure switch.

A pressure switch in the air compressor is not like a regular switch. Rather, this is the thing that can tell you when the air pressure is enough in a tank and if the air is going down. You can measure the PSI with the switch.

I have seen that people have a vast interest in the switch how does it work and what is the main purpose of the switch.

What is an Air Compressor Pressure Switch?

Air compressors pressure switch is the thing that helps to identify what is the pressure inside the tank as well as the compressor. When you want to fill a tank or anything else, you need to use the switch for turning the compressor on. Again for shutting down the compressor, you will need to switch.

This also helps to maintain the proper pressure for the compressors. You will control it by moving the switch clockwise and anticlockwise. This is the most used part of an air compressor and it needs to be maintained properly for ensuring the performance of the air compressor. This is the main protection for your compressor.

How Does the Pressure Switch Work?

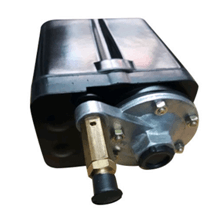

Let’s discuss how does an air compressor switches work. Well, as I have mentioned earlier, this is not like a regular switch. Instead, it comes in a rectangular housing shape that can compare with the size of your palm. It is usually mounted to the reservoir of the compressor with which the compressor can flow air. It will then monitor the air coming from the compressor tank.

The switches are designed with an air line that actually monitors the pressure of air. It moves to and from the air tank and tells the reading. Some particular elements in the switch react when air is passing through the switch. Usually, a standard air compressor switch comes with a diaphragm that compresses when exposed to air.

When you are using the compressor, it also builds up backward pressure. The tank of the compressor does this which is called cut-out pressure. This changes the shape of the diaphragm of the switch.

When the switch’s diaphragm is deformed to a particular level, the pressure switch will stop passing air. However, when the pressure level is in the right condition, the switch will continue passing air and the dance of diaphragm will be continued. From there, you can know that the compressor is working properly and you can use it.

This is the basic way of the working method of an air compressor. If you have an industrial-grade larger air compressor, the mechanism may change. But the basic workflow is the same.

Maintenance for the Air Pressure Switch

As I have suggested earlier, you should maintain the switch properly for the best performance. So, check the part regularly. For checking, start from testing the process by unplugging the air compressor. Check for any leakage from the switch.

Most often, the leaking issue happens on the diaphragm of the switch. Sometimes it may not show the right reading of the air pressure. If so, you need to fix the leaking. The best way is changing the diaphragm. This small thing is available in the local stores as well as online. If the switch is too old and you can’t solve the leaking issue, the best solution is replacing the switch with a new one. however, before you do this, take some expert suggestions.

Final Words

I hope now you have a clear concept of the workflow of an air compressor’s mechanism. Each time you turn on the air compressor, make sure that you are following the safety rules. Don’t even try to hurry for turning it on or off. Rather, do the process smoothly. For the best performance of the air compressor, take regular care of this small but essential part.