No matter its handymanship, carpentry, mechanical works or even industrial productions, air compressors are everywhere. If you belong to these or any similar profession, you definitely have to get one good quality compressor which will last for a lifetime.

Talking about choosing the right compressor, you’ll be given with two basic options- oil-less compressor and oil-driven compressors. And for most of the first timers, it’s hard to distinguish the difference between oil and oilless air compressor.

Therefore, we’ve decided to craft this whole post to explain what matters in both of these compressors, and how to choose the right one.

Let’s get going-

What Is Oil Air Compressor?

In oil filled air compressors, oil is used as a lubrication medium into the cast iron made the pump. For the high capacity workloads, these compressors also produce a tremendous amount of heat as well. Oil performs the role of a heat transfer medium as well.

Oil air compressors are likely to be more durable and more functional. Therefore, it’s a great choice for industrial compressors. As it’s lubricated by oil, the amount of noise created is also less than oil-less air compressors. Another benefit of the oil-based lubrication is, wearing and tearing are less likely to take place.

However, nothing is an unmixed blessing. So does the oil-based air compressor. There are a few drawbacks that you’ve to face with it. And the #1 of the list is- the high amount of maintenance. You’ve to put quite some regular effort to change the lubricator oil.

Another major issue is, oil lubricator is particularly made for industrial purposes. So, they’re way too heavier than what a portable compressor is. In fact, that’s quite obvious, right?

Therefore, once you buy an oil-air compressor, you’ve to plan it to install it at one place once and for all. Shifting the location or place of this compressor is a mammoth task. If you’ve to get a remote air compressor, you better don’t take the hassle and go for a portable, oil-less compressor instead.

Pros

- Heavy dusty compressing with high psi and CFM rating.

- More durable, due to less wearing both inside and outside.

- Particularly purposeful for commercial and industrial purposes.

- Produces less noise, as they use oil as a lubricator.

- Doesn’t have the hassle of installing it over and over on different sites.

Cons

- Quite heavy in weight, not remote at all.

- Requires a whole lot of maintenance.

- Costs a good chunk for the oil-based lubrication.

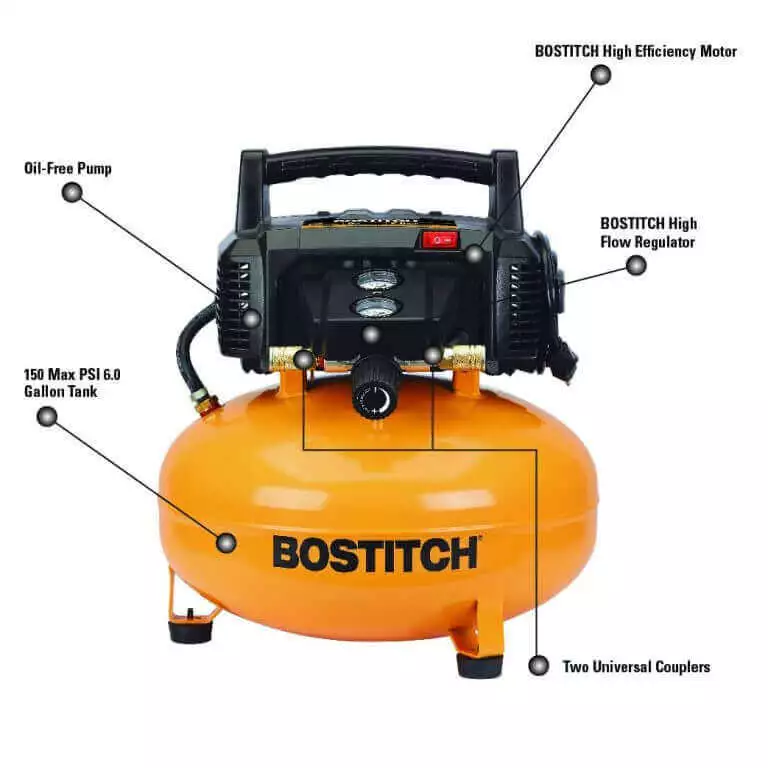

What Is Oil-free Air Compressor?

The name ‘Oil less air compressor‘ quite expresses itself. You don’t have to input oils on a regular basis the purpose of lubrication- that’s how they work. But don’t think that these compressors are not lubricated at all. They come to be kind of pre-lubricated. And their workload is way less than oiled lubricators, so they don’t need regular lubricator input as well.

The product that’s used as lubricator in these compressors is called Teflon. These models are more compact, simpler and lighter in weight. Therefore, the price is also cheaper than oil air compressors.

For remote purposes, most of these compressors are convenient. Therefore, household and non-commercial purposes are well served with them.

Apart from the lightweight and compactness, there are some drawbacks of oil-free compressors, if you look at them in a different way. As they are more exposed to the weather without any prior coating, they are more likely to damage. Also, the lifespan of the pre-provided lubricant decreases over time. So, the parts inside are more tended to wear and getting damaged.

The amount of noise is way more than oil compressors, so using them on the household environment is a challenge. But brands of today’s market seem to be careful about this issue and releasing silencer versions of these models.

Pros

- Compact design, carryable by hands.

- You don’t have to take any hassle of manual lubricating.

- Smaller and simpler in size, resulting in ease of using.

- Doesn’t take a whole lot of space to house themselves.

- A perfect fit for home and other non-commercial uses.

- Cheaper in price.

Cons

- The lifespan and functionality of the motor are used to decay over time.

- Can’t meet requirements of heavyweight compressing purposes.

- Quite noisy when operated at the household environment.

- Doesn’t have any protective coating against damage.

- Comes with a smaller tank size.

Oil vs Oilless Air Compressor- How to Choose The Right one?

So far, we were being familiar with oil vs oilless compressor and their uses. But when it’s time to select one from these two, things become quite difficult.

Why do we say that?

Well, to determine which one of these two you need, there comes a number of buying factors. The list includes usage, maintenance, the regularity of using, expected lifetime, etc.

So, we’ll be taking you through a list of buying considerable, through which you can select the right one for you-

Table of content: 5 Differences That Matter

- How Much Usage There’s Going To Be?

- How Much Noise You’re Tolerant At?

- How Much Maintenance Chore You Can Manage?

- What Is Your Expected Price-Quality Ratio?

- How Good The Warranty and Service from the Manufacturer Is?

How Much Usage There’s Going To Be?

Oil air compressors are for heavy duty and long term usage, and they require regular maintenance to let the operation go on. On the other hand, oil-free compressors are made of occasional and discrete uses. So, you don’t have to keep a sharp eye on the maintenance as well.

You see- these are two types of usage actually, which are regular and discrete. If your regular usage is quite demanding in terms of workload, an oil compressor might be the choice for you. Commercial and industrial cases are within this category.

And home users who’ve to use the compressor for non-professional, DIY projects can go for oil-free compressors. As they come to be pre-lubricated, you don’t have to worry about the maintenance as well.

How Much Noise You’re Tolerant At?

Although it’s not something directly related to the performance and capacity, but it matters a lot when you’re choosing one from oil free air compressor vs oil compressor. If you’re running a compressor at somewhere it’s mandatory to keep the noise down, oil air compressors are the automatic choice.

As the oil-free compressors come to be quite noisy for its size, you’ve to use it either at an open place or inside a soundproof room. But the good news is, there are many compact models available who are both oil-free and less noisy at the same time.

How Much Maintenance Chore You Can Manage?

In industrial production processes, there is always someone standby to maintain and operate machines like air compressors. So, maintaining the compressor for constant performance is kind of their duty. Therefore, the heavy checklist of maintenance chore for oil compressors is no headache for them.

But if you stand alone as the only user of your compressor, you might not provide ample attention to the maintenance of it. As consequences, the lifetime and performance of the compressor will be less.

But getting an oil-free air compressor might be a good idea in this regard. The tasks like air filter cleaning, tank cleaning, leak repair, etc are less likely to take place.

Keep an eye on this fact when you’re choosing between oilless vs oiled air compressor.

What Is Your Expected Price-Quality Ratio?

No matter you buy a compressor within 100 bucks of 5000 bucks, it’s going to serve you with a certain value. And this ratio of price and quality varies from model to model. Before investing after a complicated tool like an air compressor, you’ve to do some serious analysis on that.

You can start with the amount of work you can expect from a compressor throughout its lifetime. Diving that by the total cost of the compressor might give you some solid idea.

The cost of a compressor includes-

- Equipment and installation cost.

- Maintenance and repair cost.

- Electricity and lubricator cost.

If the expected price vs quality ratio lies within your capacity, you can find out the winder from oil lubricated air compressor vs oil free compressor whatsoever.

How Good The Warranty and Service from the Manufacturer Is?

Top notch brands who produce air compressors are likely to offer a definite and free repair/replacement service for their product. And that completely depends on how the brand value is.

Giant brands like Makita, Campbell Hausfeld, DeWalt, Senco, California Air Tools, etc have quite an impressive scheme in this regard. Smaller and newbie brands may offer you a cheaper price, but you won’t get the assurance that you’d get from promising brands.

We think it even more important if you’re about to buy an air compressor for industrial purposes. A sudden malfunction into the machine might cost you tons of workloads gone in vain. So, having a quick warranty scheme (along with on-spot service) is even more important in this regard.

Conclusion

In a nutshell- oil compressors are the heavy, bulky and highly capable compressors, mostly for industrial and commercial purposes. And oil-free compressors are the compact, smaller and miniature versions of them. Hopefully, picking one from both of these two had become way easier for you after going through the whole post on oil vs oilless air compressor.